2024 Grower Pesticide Course

Visit www.opep.ca to sign up today. Manuals available at Belleville, Brighton, Colborne and Napanee for pick up.

Visit www.opep.ca to sign up today. Manuals available at Belleville, Brighton, Colborne and Napanee for pick up.

Visit www.opep.ca to sign up today. Manuals available at Belleville, Brighton, Colborne and Napanee for pick up.

Visit www.opep.ca to sign up today. Manuals available at Belleville, Brighton, Colborne and Napanee for pick up.

2023 OFA Regional Meetings

Join us at the 2023 OFA regional meetings – Ontario Federation of Agriculture

TCO Agromart Partners and employees (Karen Harder, Dexter Harder, Sandra O’Neill, Terry O’Neill, Patrick O’Neill and Larry Hutchinson) came together to find a way to help and give back when they found out Sarah Wilson’s (Dexter and Karen Harder’s daughter) devastating news. The TCO team was inspired to find a way to help and decided to bake cookies to sell for a donation to Cancer Care at Belleville General Hospital.

“This stirring tribute in support of a coworker reminds us it is through our relationships that we get the support we need to tackle some of the greatest challenges”

Congratulations TCO Agromart on raising $5,220 for a wonderful and personal cause!

When bad news struck Sarah Wilson’s family again, her coworkers at TCO Agromart Ltd. were inspired to find a way to help. Little did Sandra O’Neill know how far her original idea of baking cookies to sell for a donation to Cancer Care at Belleville General Hospital would take them!

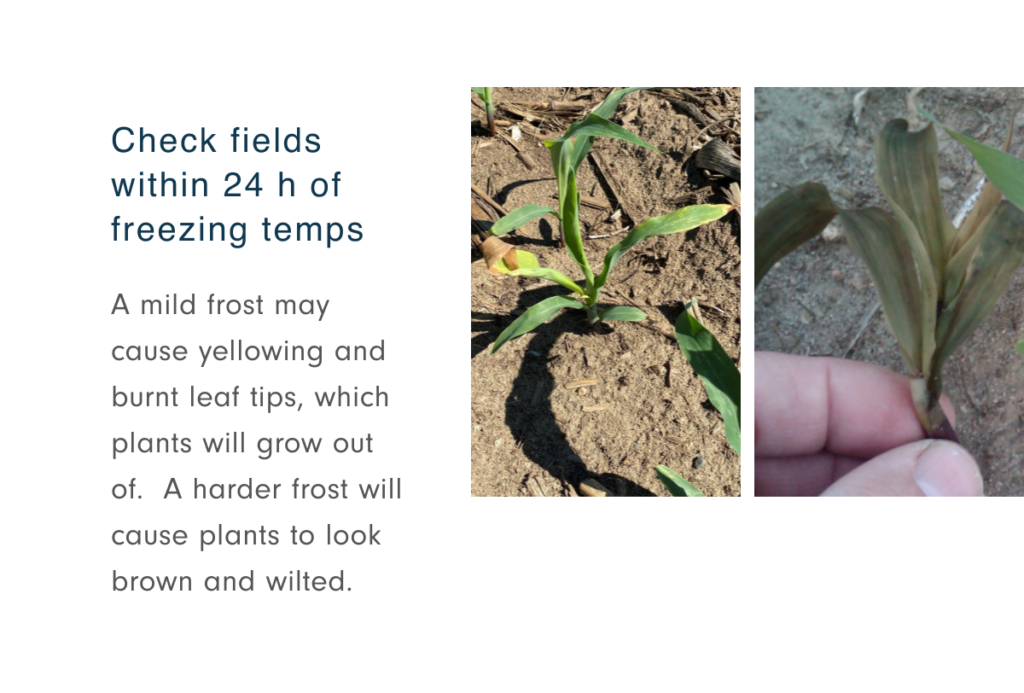

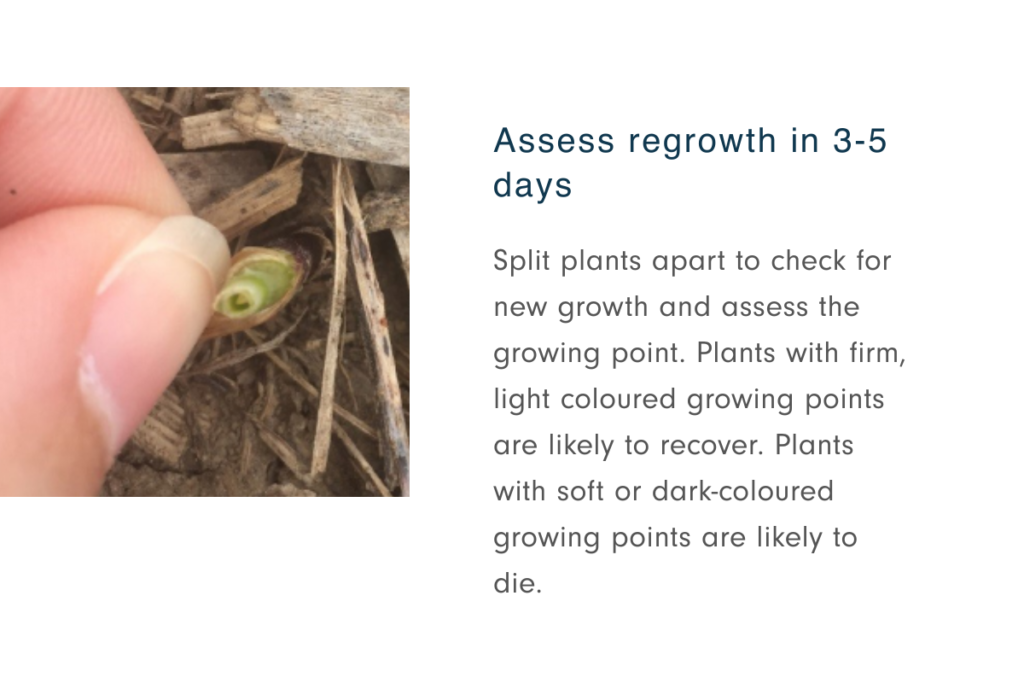

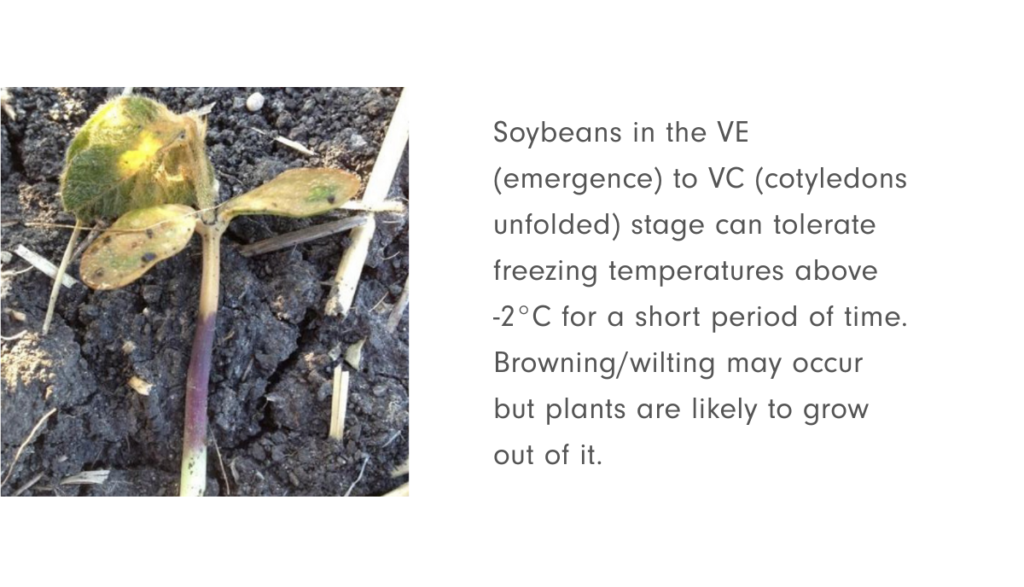

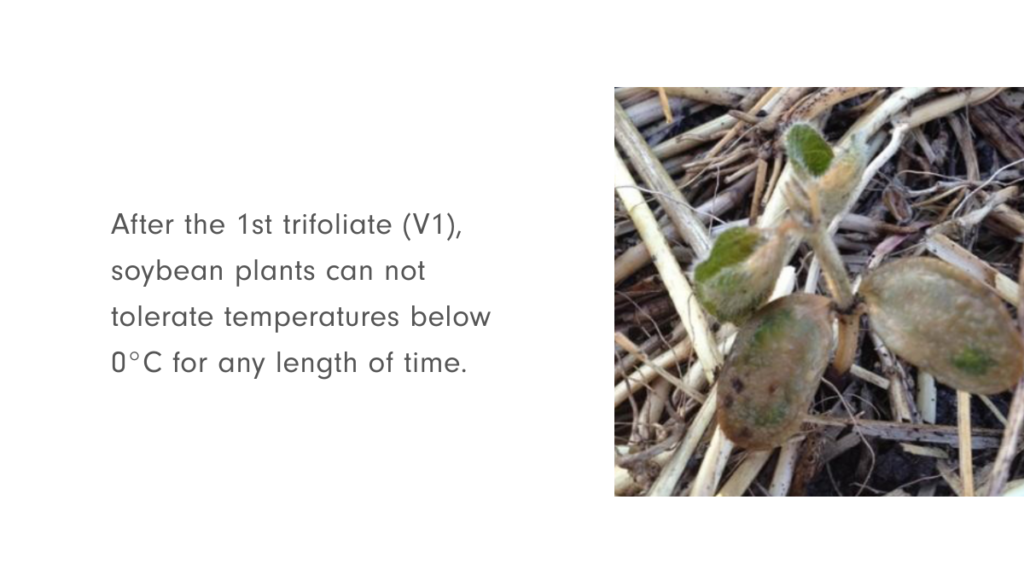

A message from our local Bayer Market Development Agronomist, Katie Macfarlane. A few things to consider this week with a lot of fields emerging and some cool nights still in the forecast.

CornCorn is less susceptible to frost injury before V5 (Corn growth staging guide) because the growing point remains below ground. |

The growing point of soybeans is exposed at emergence, so they can be more susceptible to frost damage than corn (Soy growth staging guide). However, complete death of the plant usually won’t occur unless temperatures are below -2°C for several hours.

Please join us for a free information session and dinner! RSVP by Friday April 7th your attendance if you’re interested.

PurYield provides yield and bottom-line benefits in all row crop production, including corn, soybeans and wheat. PurYield is a granular Enhanced Efficiency Fertilizer that consists of urea with an innovative, proprietary polymer coating. The release rate is driven by the soil temperature.

Advantages:

Application methods: